Huachuan Group has been upgrading its power plants since 1996 when it became involved in the thermal power industry. in 1996, the enterprise invested 42 million yuan in the construction of a 6,000-kilowatt thermal power plant.

In 2001, the enterprise invested 280 million yuan to invest in one of the key technological transformation construction projects in Yiwu City, the garbage incineration project; in 2004, the second phase of the garbage incineration power plant began construction, with an annual power generation capacity of 130 million dry watt hours.

In November 2016, Zhejiang Huachuan Industrial Group Co., Ltd. and Shenzhen Energy Environmental Protection Co., Ltd. jointly invested in a large-scale waste incineration power generation specialized company - Zhejiang Huachuan Shenneng Environmental Protection Co. The company has a daily waste treatment capacity of 3,000 tons and an annual power generation capacity of more than 300 million degrees; the plant has an environmental science education center, a book bar, a constant temperature swimming pool and other ancillary facilities.

Hwachuan Shenneng has a daily treatment capacity of 3,000 tons of domestic waste.

Dispose of 1 million tons of garbage per year

Digested the city's domestic waste in Yiwu

Annual power supply of about 300 million kWh

Saves about 90,000 tons of standard coal per year

Emission reduction of about 243,000 tons of CO₂, energy saving and consumption reduction.

Slag from waste incineration can be made into environmentally friendly bricks

Calculated on the basis that 1 ton of slag can be made into about 500 environmentally friendly bricks after treatment

1 day's slag can be made into 300,000 environmentally friendly bricks

1,200 meters of 7-meter wide roads can be paved

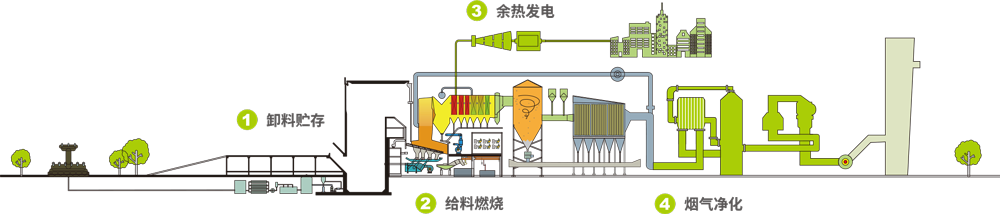

1. Unloading and storage

Domestic garbage is transported to the waste incineration power plant by special garbage trucks, and then unloaded into the closed garbage pool after weighing and measuring by automatic weighing scale, and then sent into the incinerator by automatic garbage crane grapple after stacking and fermenting in the garbage pool for 5-7 days.

2. Feeding and burning

Garbage into the feed hopper, through the feeder to the multi-stage mechanical grate incinerator consisting of drying section, combustion section and combustion dike section, fully combusted on the grate for about 1.5h ~ 2h after the formation of thermal scorching rate of 3%, the composition of the stable slag. Slag falls into the slag machine discharged to the slag pond.

3. Waste heat power generation

Domestic garbage is fully combusted on the grate to produce high-temperature flue gas; the high-temperature flue gas is exchanged with the waste heat boiler to produce superheated steam: the steam pushes the turbine generator set to generate electricity, realizing the recycling of energy.

4.Flue gas purification

The project adopts international advanced and mature, full-featured flue gas purification system and carries out flue gas "de-whitening" treatment: SNCR (selective non-catalytic reduction and dephosphorization) + rotary spray semi-dry de-acidification + dry de-acidification + activated carbon spray adsorption + fabric dust collector + mixed method of de-acidification + SCR (Selective Catalytic Reduction and Degassing). The purified flue gas is ultra-low emission, and the emission data reaches or even better than the EU standard.